| Tipo di Apparecchiature |

|

|

Chengnan Industrial Park, Rudong, Nantong, Jiangsu, 226400

Cina

|

Informazioni Sullo Staff

Contatti Utili

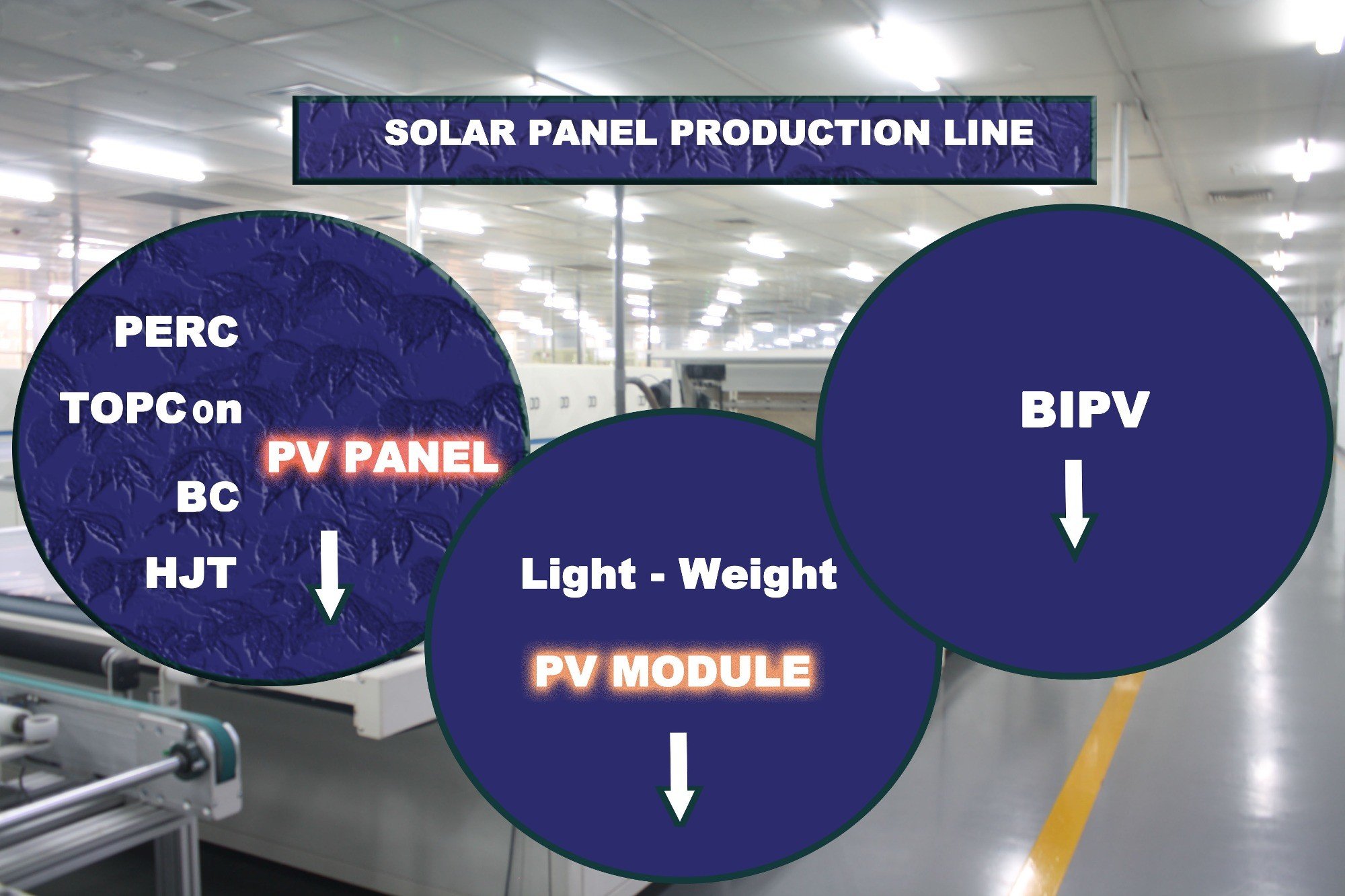

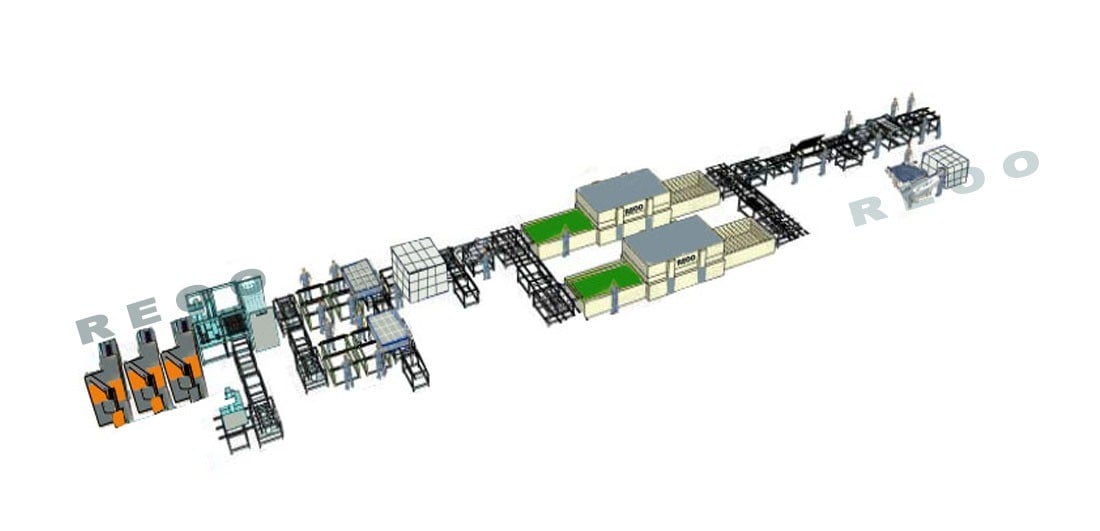

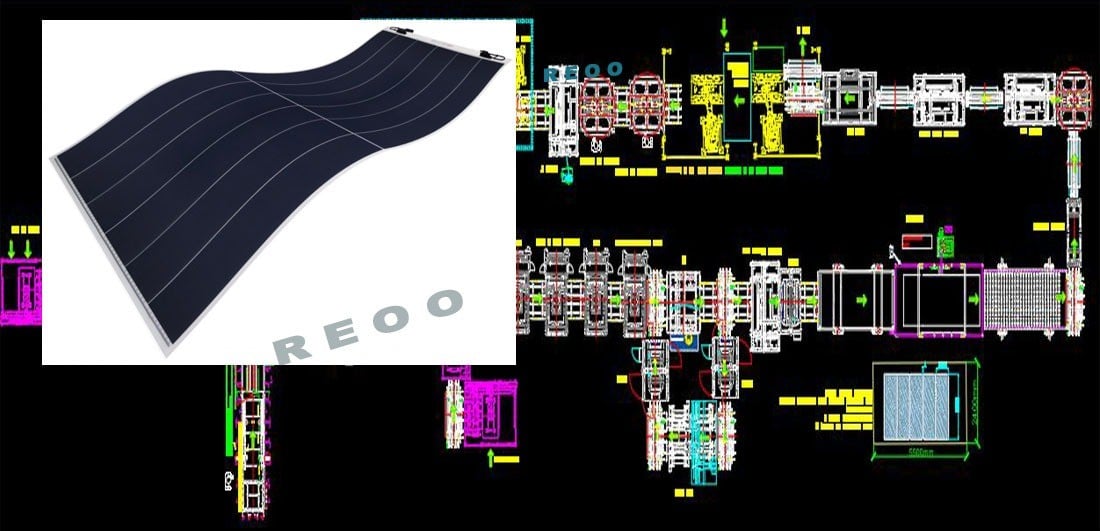

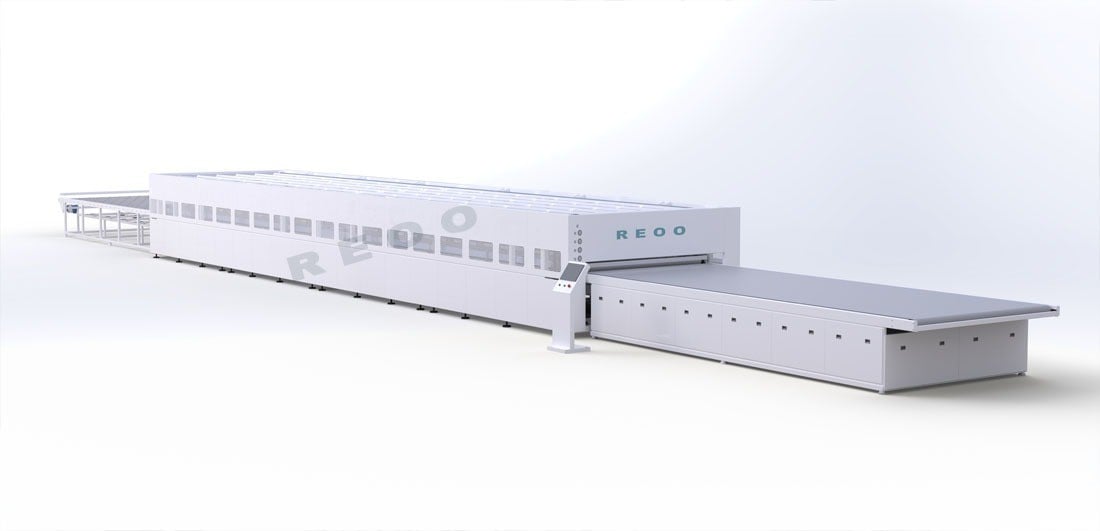

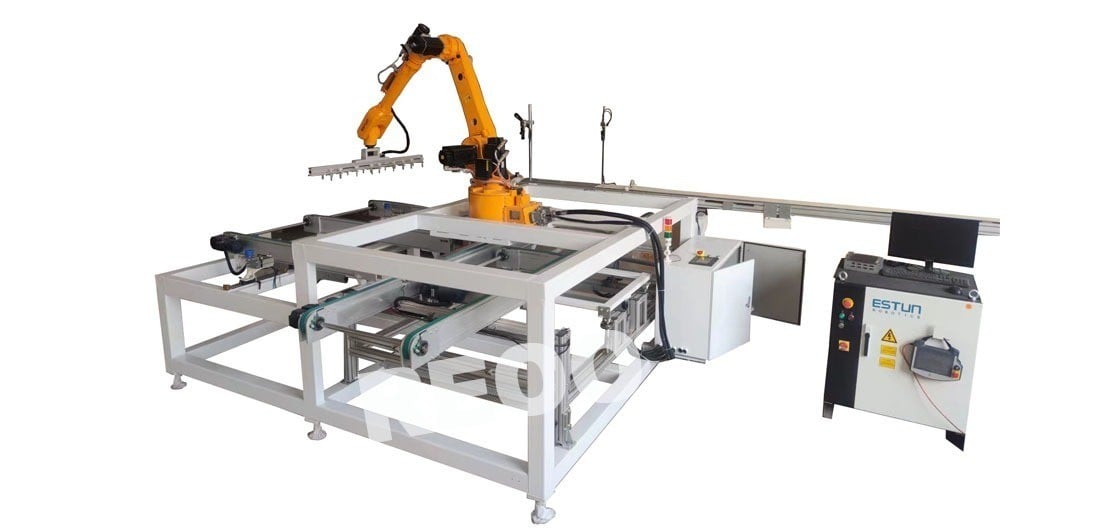

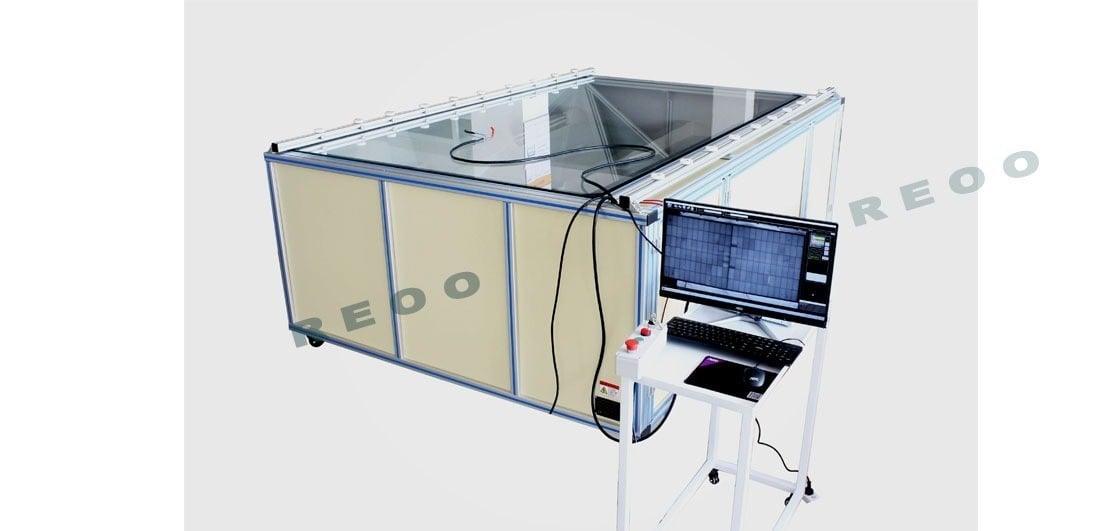

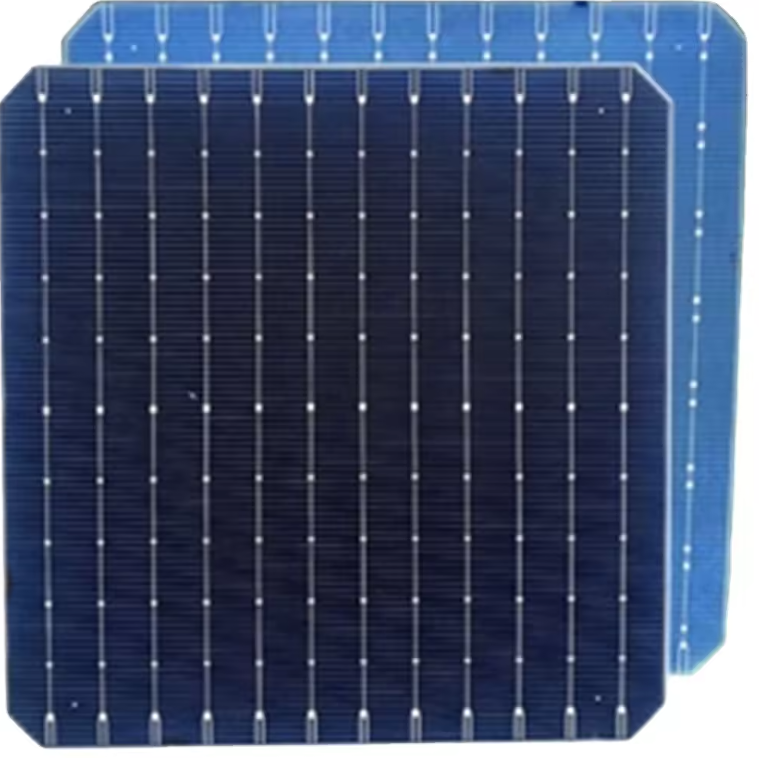

REOO Technology Co., Ltd. è stata fondata nel 2005 ed è specializzata nella progettazione, ricerca, sviluppo e produzione di macchine per la produzione di pannelli solari basate su una soluzione chiavi in mano, modello one-stop. Forniamo progettazione del layout, installazione in sede, formazione e servizio post-vendita a lungo termine. La nostra linea di produzione può produrre pannelli solari a celle PERC, TOPCon, BC, HJT, moduli solari leggeri e moduli BIPV. La produzione annua della linea di produzione varia da 5 MW a 1 GW. Produciamo principalmente apparecchiature quali laminatori, macchine per il taglio di celle, macchine per il taglio di pellicole, stringer, macchine per impaginazione, macchine per etichettatura e stringing, tester EL, tester IV, macchine per incorniciatura, trasportatori di assemblaggio e altri.

La sede centrale dell'azienda è situata a Nantong, Jiangsu, a circa un'ora e mezza di macchina dall'aeroporto di Shanghai Hongqiao o con il treno veloce. L'azienda dispone di due basi di produzione, una per i laminatori e una per le apparecchiature ausiliarie, oltre a centri di ricerca e sviluppo e centri commerciali.

Con 28.000 metri quadrati di terreno di proprietà, l'azienda dispone di laboratori ed edifici per uffici standardizzati, inclusi i reparti di ricerca e sviluppo, produzione, marketing, amministrazione, finanza e servizio post-vendita.

Grazie alla nostra attenzione all'elevata automazione, ai bassi costi, alla funzionalità personalizzata e al tempestivo servizio post-vendita per le linee di produzione di pannelli solari, le nostre apparecchiature sono state esportate in oltre 80 paesi in tutto il mondo negli Stati Uniti, Canada, Europa, Sud America, Australia, Corea , Sud-est e Asia centrale, Africa, e ha guadagnato elogi da parte dei nostri clienti.

| U.S.A. | Abloomax |

| Tipi di materiali | Sigillante, Ribbon Piombo, Ultra Clear Glass, PET Laminato, EVA, Connettori, Cornici, Celle, Rame, Scatola di Giunzione Silicone |

| Tipo di Cavo | Unipolare |

| REOO Company is a reputable provider of production line solutions that is worth to work with and would always recommend their products. Their company has rich experience in customized design, overseas installation, and timely after-sales service. They have customers all over the world and can meet the needs of different customers. All in all, it is a reliable partner. |

| -- Catherine chen, Techwise Solar Technology Co., Ltd. |